Application:-Make a leak test system. Write PLC program for leak test system using ladder diagram language.

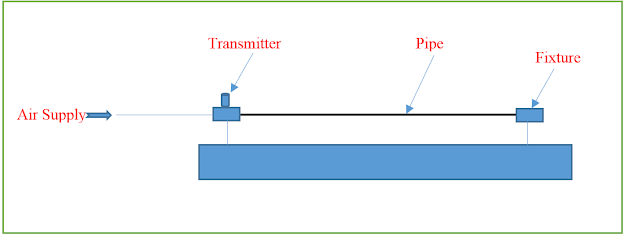

Diagram:-

Explanation:-

As per the above

application, there is one pipe in the system. We need to check its leakage by

applying pressure up to 4- 5 bar. For leakage testing, the first pipe will be put

into the fixture and one side pipe will be blocked completely. From the other side, the pressure will be applied.

The transmitter will read

the pressure. Once the pressure achieved into the pipe, the system will close the

inlet pressure valve and hold pressure into the pipe. If there is no pressure

drop for 1 minute, the pipe is ok and if the pressure drop measured during 1 minute, the pipe is leaked.

PLC

program:-

Write the ladder program for the above application using

ladder diagram language. Here for ladder logic, we can use any supported PLC

system like S7-1200, S7-300, S7-1500 or any other PLC which can support this

instruction. For PLC logic we need digital inputs and outputs.

Digital

inputs:-

Start Button=I0.0

Digital Output:-

Inlet Valve=Q0.0

Ok lamp=Q0.1

M

Memory:-

MD24= Set Pressure

MD20=Actual Pressure

|

Network

1:-Inlet valve for air supply |

Network 2:-Inlet valve reset when pressure achieved

Network

3:-Indication timer for ok pipe

PLC

program Explanation:-

In network 1, the inlet valve (Q0.0) will on when the start button (I0.0) is

pressed. Here we used set coil so the output will be set after the start button

pressed.

In network 2, the inlet valve will be off when Actual pressure (MD20) is

greater or equal to set pressure (MD24).

In network 3, if the pressure will not drop from the pipe for 60 seconds, ok

indication lamp will be on.