Clock memory function in the S7-1200 PLC.

Application:-Understand the concept of clock memory and system memory function in the S7-1200 PLC using example

Explanation:-

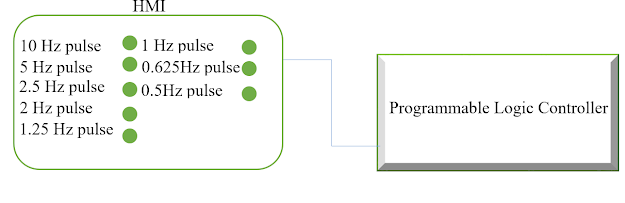

To understand the system and clock memory we can use S7-1200 PLC. Clock memory configure byte and that cycle of individual bit on and off at fixed interval. These bits can be used in the program for controlling or for some time based logic. We can use these bits for triggering function.

PLC program:-

Write the ladder program for above application using ladder diagram language. Here for ladder logic we can use any supported PLC system like S7-1200, S7-300, S7-1500 or any other PLC which can support this instruction. For PLC logic we need digital inputs and outputs.

Select clock memory and define address in the

hardware confugration.For example take byte 0 for clock memory so form M0.0 to

M0.7 can be used for clock pulse.

Digital Output:-

OP 1=Q0.0

OP 2=Q0.1

OP 3=Q0.2

OP 4=Q0.3

OP 5=Q0.4

OP 6=Q0.5

OP 7=Q0.6

OP 7=Q0.7

M memory:-

M0.0=10 Hz pulse

M0.1 =5 Hz pulse

M0.2=2.5 Hz pulse

M0.3=2 Hz Pulse

M0.4=1.25 Hz Pulse

M0.5=1 Hz pulse

M0.6=0.625 Hz Pulse

M0.7=0.5 Hz Pulse

PLC program Explanation:-

In network 1, OP 0 is blinking at 10 Hz frequency

In network 2, OP 1 is blinking at 5 Hz frequency

In network 3, OP 2 is blinking at 2.5 Hz frequency

In network 4, OP 3 is blinking at 2 Hz frequency

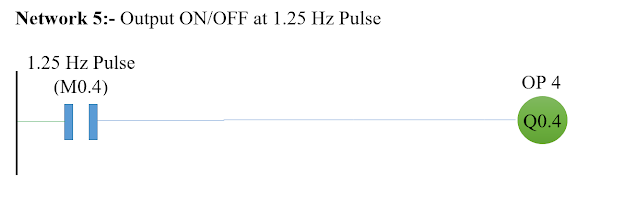

In network 5, OP 4 is blinking at 1.25 Hz frequency

In network 6, OP 5 is blinking at 1 Hz frequency

In network 7, OP 6 is blinking at 0.625 Hz frequency

In network 8, OP 7 is blinking at 0.5 Hz frequency