Fundamentally, there are two types of control loop;

1.

open loop control

2.

Closed loop feedback control.

In open loop control, the

control action from the controller is independent of the "process

output" (or "controlled process variable").

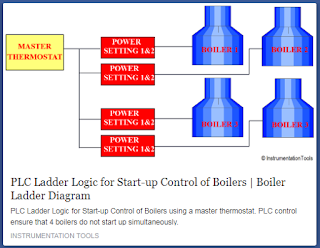

A good example of this is a central heating boiler controlled only by a

timer, so that heat is applied for a constant time, regardless of the

temperature of the building. (The control action is the switching on/off of the

boiler. The process output is the building temperature).

In closed-loop control, the

control action from the controller is dependent on the process output. In the

case of the boiler analogy, this would include a thermostat to monitor the

building temperature, and thereby feedback a signal to ensure the controller

maintains the building at the temperature set on the thermostat.

A closed loop controller, therefore, has a feedback loop which ensures

the controller exerts a control action to give a process output the same as the

"Reference input" or "set point". For this reason,

closed-loop controllers are also called feedback controllers.

The definition of a closed

loop control system according to the British Standard Institution is 'a control

system possessing monitoring feedback, the deviation signal formed as a result

of this feedback being used to control the action of a final control element in

such a way as to tend to reduce the deviation to zero.

Likewise, a Feedback Control System is a system

which tends to maintain a prescribed relationship of one system variable to

another by comparing functions of these variables and using the difference as a

means of control.

The advanced type of automation that revolutionized manufacturing,

aircraft, communications, and other industries, is feedback control, which is

usually continuous and involves

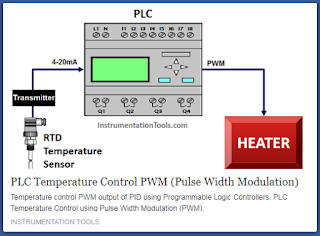

taking measurements using a sensor and making calculated adjustments

to keep the measured variable within a set range. The theoretical basis of

closed-loop automation is control theory.