S7-1200 Configuration in TIA portal software.

This is PLC Program for the S7-1200 PLC configuration in TIA portal software.

Problem Description:-

Write the PLC program for the S7-1200 PLC configuration in the TIA portal software.

Problem Diagram

////////////////////////////////////////////////////////////////////////////////////////////

Problem Solution

Problem Solution

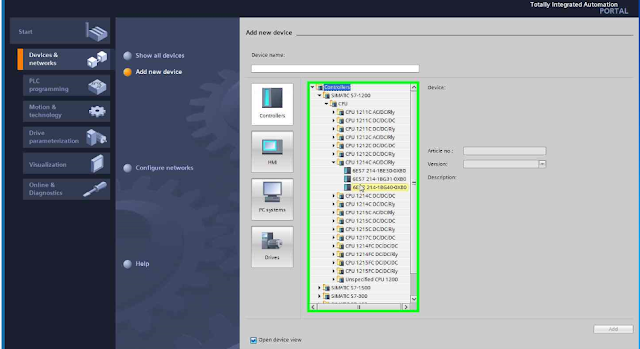

Open TIA portal software in the PC or laptop. Create new project in the software and take hardware from the hardware list.

Select required PLC model and save the configuration.

Program

Here is PLC program for the S7-1200 PLC configuration in the TIA portal software.

List of inputs/outputs

Inputs List:-

Outputs List:-

M memory:-

Configuration for the S7-1200 PLC in TIA portal software.

Open TIA portal software from your desktop and create new project in the software. Once project is created, select devices (controllers, HMI. PC system, Drives) from the list.

After selecting controller, select CPU.

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Select required PLC model from the list as shown in figure (Consider here CPU 1214

ACDCRLY)

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Select serial no of the PLC as shown in figure (available on hardware).

Select add option and save the program

Your configured CPU (PLC) is here!!

Note:-Application is only for learning and educational purpose .Above application may be different from actual application. This application can be done in other PLC also. Users are responsible for correct operation of the PLC system and for any possible injuries and or material damages resulting from the use of this program. It is necessary to take care of safety during implementation, installation, maintenance and operation.

All parameters and graphical representations considered in this example are for explanation purpose only, parameters or representation may be different in actual applications. Also all interlocks are not considered in the application.