Application:-Explain OFF delay timer using example. Also draw electrical

diagram and PLC program for example

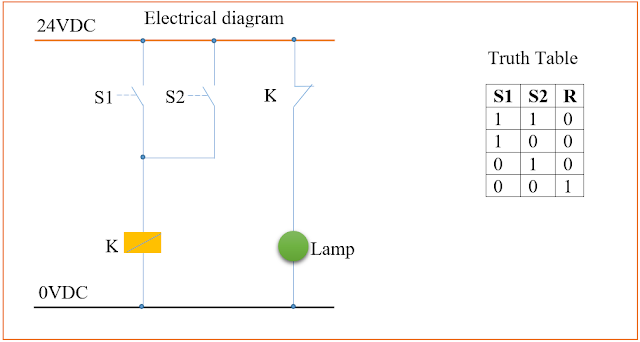

Components:-Programmable logic controller, Electrical

panel, wires, 24VDC switch with NO contacts, 24VDC solenoid valve, and 24 VDC OFF

delay timer.

Diagram:-

Explanation:-

Consider one example

for OFF delay timer explanation. For example there is a valve in our application

and we need to close it after 20sec when switch S1 is pressed. So as shown in

above circuit supply will pass from No contact of the switch and will go to

timer supply. When switch is pressed timer will start first and operate valve

and meanwhile off delay will start so after time valve will be close

automatically.

PLC

program:-

Write the ladder program for above application using

ladder diagram language. Here for ladder logic we can use any supported PLC

system like S7-1200, S7-300, S7-1500 or any other PLC which can support this

instruction. For PLC logic we need digital inputs and outputs.

For our application start switch S1 is digital input

and valve is the digital output. So define digital input address and output

address as per below explanation,

Digital

inputs:-

Start switch S1=I0.0

Digital Output:-

Valve=Q0.0

PLC

program Explanation:-

In network 1

we have taken NO contact of Start switch S1 (I0.0) so when switch is pressed,

timer and valve (Q0.0) will start. The set time is 20sec so timer will generate

OFF command to stop valve (Q0.0).

Here PT is preset time

at which we can set time and ET is elapsed time at which we can monitor time.

Do not mix up the pulse timer and OFF delay timer. In pulse timer, timer needs

pulse of the digital input for operation and in OFF delay timer, timer needs

digital input for operation.